Flushing fluid specifically formulated for masport.

Masport vacuum pump troubleshooting.

Masport vacuum pumps require little regular maintenance except for flushing the pump.

Flushing is for general maintenance to prolong the life.

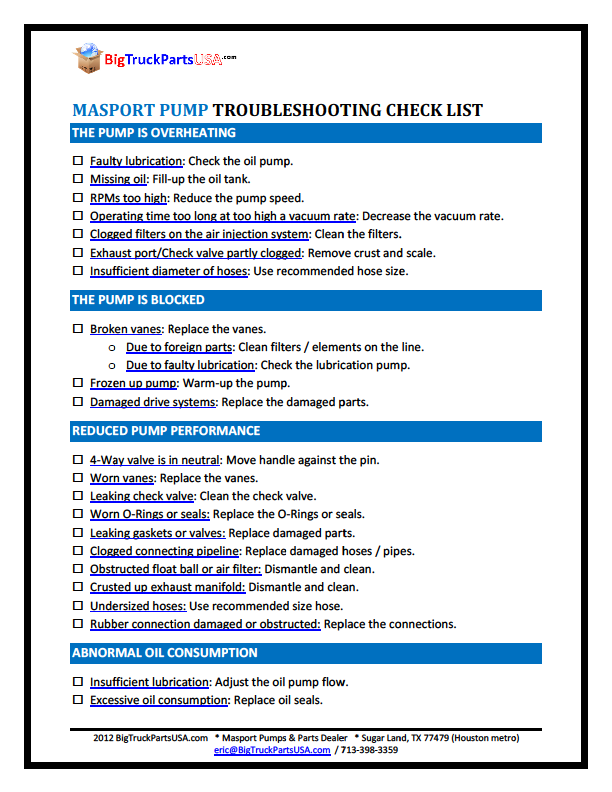

The pump overheats potential causes to check and resolve.

The pump overheats potential causes to check and resolve.

Bleed the oil pump.

This does not allow the ring to form properly.

Masport s customer service representative matt gropp provides a guided walk through on how to rebuild your masport hxl series vacuum pump.

After startup observe the transparent oil lines coming from the oil pump to confirm that oil is flowing from the oil pump to the cylinder ports.

800 228 4510 email.

Pour 1 to 2 oz.

Masport incorporated 6801 cornhusker highway lincoln ne 68507 usa phone.

Masport pumps specializes in the manufacture and supply of vacuum pumps systems components and accessories for the vacuum truck industry.

30 to 60 ml of pump oil into the vacuum pump inlet and rotate the pump by hand several times to coat the cylinder with a fresh film of oil.

If the unit is gear driven make sure vibrations are not from gear itself.

This should be done weekly or anytime liquid or solids have been allowed to enter the pump.

Pro pack plus 2500 engine drive system features and benefits designed for tank.

Vacuum pumps common problems and troubleshooting.

Continued operation above recommended maximum vacuum and pressure levels.

Rpm in excess of recommended levels.

Inadequate level of oil or no oil in the pump.

Masport s sales manager john gilbert provides a step by step guide on how to flush your vacuum pump.

Make sure pump is not started against blank suction subjecting it to immediate high vacuum.

Check pump mounting and alignment.

Microsoft word masport vacuum pump troubleshooting check list author bcarte3 created date 2 9 2012 7 19 20 am.

For further issues or additional information contact an authorized masport.